Environmental Initiatives / ISO14001

ISO14001

-

-

We are an Environmentally Conscious company!

Nestled between Japan’s Central and Southern Alps ranges, Shinshu Komagane is blessed with abundant water resources, and we run our business reaping the benefits of the nature around us.

Being in such a natural environment, as a surface processing manufacturer we understand the heavy responsibility we have to avoid environmental burdens like industrial pollution, which could lead to the loss of biodiversity, and as such, we have taken steps to avoid endangering this biodiversity, and are actively pursuing environmental initiatives, including the development of environmentally friendly products.

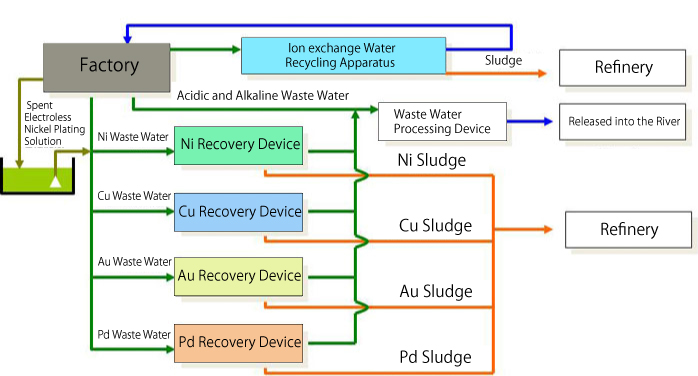

Recycling of Waste Water and Solutions

In most cases, with the exception of some expensive precious metals, the spent plating solution from plating factories is processed into a general sludge, which is then taken by industrial waste removal contractors for disposal.

We are currently developing a proprietary technology to selectively remove copper and nickel from the spent solution, which can then be recovered as valuable resources. This initiative should decrease the burden on the environment by decreasing the amount of industrial waste, while also decreasing costs by reclaiming resources.

-

Copper Sludge

Sludge created by selectively removing copper from spent electroplating solution

-

Nickel Sludge

Sludge created by selectively removing nickel from spent electroplating and electroless plating solutions (Phosphorous quantities are below standard values)

-

Nickel Reclamation Device

Spent electroless nickel plating solution and wash water are reclaimed, and nickel sludge is created.

Zero Emissions

An Odorless Plating Factory

At our factory, there is virtually no odor of the chemicals used in plating factories. With a clean workplace, the fumes given off by the plating baths are sucked in and go through an air purifier before being exhausted outside.

-

Clean-up mechanism

-

Air Purifier

Waste-water Recycling Center

The Newest Waste-water Recycling Equipment

-

-

・Recycles up to 40 t/h of factory waste water ⇒ Return to the factory

・The enriched waste water is separated into 7 types: nickel, copper, chromium, palladium, gold, alkaline, and acidic.

↓

Reclamation of Metal Resources

・We have an underground tank (150t) for plating solution spillage in case of emergency.

↓

We aim to minimize the environmental burden in times of disaster

-

-

In the factory, the plating solution lifetime is maximized through use of vacuum condensers, while efforts are made to reduce the amount of enriched waste water, and there are 9 air purifiers installed to prevent atmospheric pollution.

We aim to further develop a closed system employing in-process recycling and a large-scale waste water recycling device, with the goal being a completely closed plating waste water system.

Waste-water Recycling Flow

In-house Developed Nickel Reclamation Apparatus

-

-

In many plating factories, the spent nickel plating solution is treated as industrial waste.

We at Tsukada Riken believe this is a valuable resource, and have developed our own technology to selectively recover only a highly pure level of nickel from the spent solution, and reclaim it as a resource.

This both drastically reduces the processing cost, and reduce the impact on the environment.

Composition chart of 1kg of nickel sludge recovered with the Reclamation Apparatus

| Nickel Content | Phosphorous Content | Water Content |

|---|---|---|

| 0.1979Kg(19.79%) | 0.000206Kg(0.0206%) | 0.486Kg(48.6%) |

*(The nickel and water content may vary.)

Reduction of Environmentally Hazardous Materials

Environmentally Friendly Plastic Plating Method “Direct Plating”

Reduced CO2 Emissions

In order to fight global warming (reduce CO2 emissions) and promote energy conservation, we have taken such actions as implementing renewable energy sources and purchasing hybrid vehicles for our company cars. For renewable energy sources, we installed solar panels on the roof of our headquarter factory building and on the roof of the employees parking lot (generating 75000 kw of power). By installing solar panels over the employees parking lot, we also created a multi-purpose space that can be used for outdoor activities.

-

Solar Electricity Generation Initiative

We have installed solar panels, and produce electricity at our factory.

-

Solar Electricity Generation Initiative

The area below the solar panels is used as a multi-purpose space for outdoor activities, etc.

-

LNG Gas Boiler

We switched from A-grade oil to LNG. The image shows the boiler, water heater, and furnace.

Use and Updates of Energy-efficient Devices

-

Inverter Rectifier

-

Exhaust Device Inverter Control

-

Intake Device Inverter Control

-

Inverter Compressor

-

Inverter Air Chiller

Uses of Well-water Air-cooling System

-

Work Area Well-water-cooled Air Conditioning

-

Well-water Cooled and LNG Heated Air Intake

-

Water-cooled Air Intake

Energy-saving Indoor Lighting

-

Indoor LED lighting

-

Outdoor LED Sensor Lighting

-

Motion Sensor Automatic Lighting Control

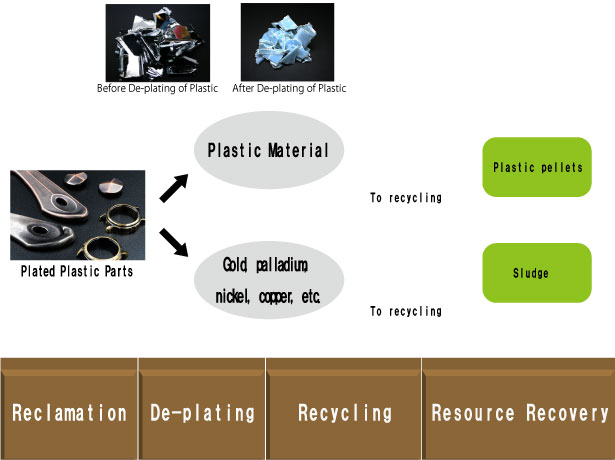

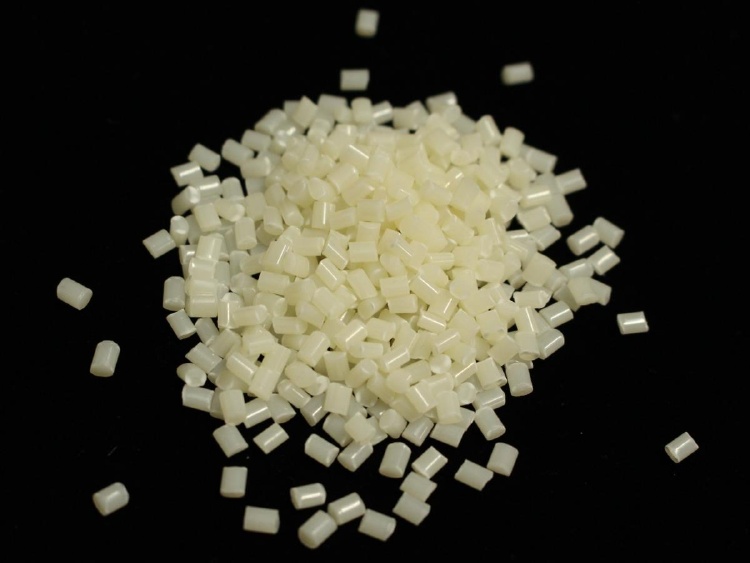

Recycling of Scrapped Plastic

Recycling Plated Plastic Parts Success at Reclaiming Metal Resources

Many plated parts are used in cars, home appliances, computers, cell phones, and more. Metals like gold, palladium, nickel and copper are used in the plating of plastics and circuit boards. Currently, when they’ve outlived their usefulness, most of these plated parts are treated by companies as industrial waste, and sent to landfills.

We use a proprietary method to remove the plating from the plastic, then recovering the plastic and metal as reusable resources.

We recycle waste plated parts and print circuit boards (that are no longer useful) as valuable resources.

-

Recycling of Plastic

-

Sludge

-

Plastic pellets