Tsukada Riken Industry continues to add value to products with our plating skills, and by continuously developing new applications for plating, as well as developing processes to reduce the impact to the environment,

we aim to surpass our customers’ expectations. As a plating manufacturer, we have a depth and breadth of expertise that allows us to create creative and original new technologies.

Furthermore, we strive to be a leading surface treatment company that is environmentally responsible and in harmony with our society.

Hexavalent Chrome-free Etching

CHROMIC ACID FREE ETCHING

Our technology for plating plastics allows us to put an authentic glossy metallic luster on light-weight plastics, which can be used in many applications such as home electronics, computers, smart phones and plumbing fixtures. It is also used in a variety of automotive applications in order to reduce weight, as well as for decorative purposes. The most common use of plastic plating is for ABS, and the standard method to achieve strong adhesion has been the etching method using hexavalent chrome.

However, with the hazards of hexavalent chrome being recognized globally, there has been a push for plating technology that doesn’t require chromic acid.

We have pursued research and development toward creating processes to plate not only ABS, but also other resins and engineering plastics, without using hexavalent chrome.

We are already able to mass produce hexavalent chrome-free plating on PA and PPS plastics, LCP, PEI, POM, etc. for uses in automotive interiors and electronics parts.

And we are continuing to develop new hexavalent chrome-free etching processes in conjunction with Kanto Gakuin University’s Material & Surface Engineering Research Institute.

Examples of Production and Development of Chromic Acid-free Etching Methods

-

・Etching methods using chemicals other than hexavalent chrome

・Environmentally responsible process using chemical-free surface-reforming water

・Etching method with a special process for resin surface reforming

・Combination with the Dry Process method, etc. -

-

Dry Process Device

-

Etching Metho

-

If you have any questions or requests regarding Hexavalent Chrome-free etching pertaining to prototype plating or mass production, please Contact Us.

MID

MOLDED INTERCONNECT DEVICE

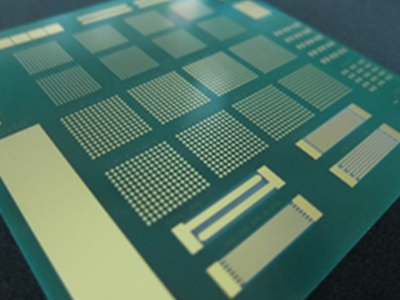

MID(Molded Interconnect Device)

-

MID (Molded Interconnect Device ) is a “three-dimensional molded plastic form made with integrated electronic circuits”. Because standard flat circuit boards are mounted flat, there is a limit to how small and thin electronic devices can become when pursuing high functionality.

By using MID 3D circuit boards, the possibilities for making electronic devices even smaller/thinner are increased. -

-

MID Molded Interconnect Device

-

General PCB

-

Advantages of using MID

<Weight Reduction>

Because we can create the pattern directly to the plastic form, there is no need to prepare or screw down a separate base, leading to weight reduction.

<Miniaturization>

Three-dimensional implementation is possible, leading to the miniaturization of space-saving parts.

<Simplification of Assembly>

The reduction of the number of steps to assemble a circuit board module results in increased precision.

We are currently using a method known as LDS (Laser-Direct-Structuring) for prototype plating

Besides LDS, other plating processes are possible for a variety of MID methods. Please feel free to Contact Us.

Plating of 3D-printed Items

3D PRINTER PRODUCTS

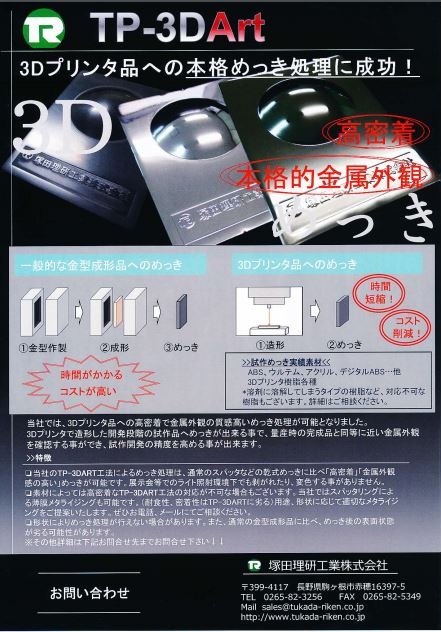

TP-3D Art (Plating of 3D printed objects)

-

It is now possible to plate 3D printed items with a high-quality metallic finish which also has high adhesion.

Technical Cooperation::Stratasys Japan Ltd. -

With a special process, the layering from 3D printing can be given a glossy finish.

Technical Cooperation::Stratasys Japan Ltd. -

We have also plated wheels (40 cm diameter).

Produced by: Stratasys Japan Ltd; SWANY Co., Ltd; Zero-Warp Ltd.

Characteristics of TP-3D

- With our TP-3D Art method plating process, we can achieve better adhesion and a more metallic appearance when compared to dry plating methods like sputtering. The plating doesn’t peel or change color even under the strong lighting environment found in places like exhibition events, etc.

- Depending on the material, the strong adhesion of the TP-3D Art method may not be possible. We can also perform thin-coat metallizing with sputtering. (This is inferior to TP-3D Art regarding corrosion and adhesion.) We can recommend the best metallizing solution for the use or shape of the object. Please Contact Us either by telephone or e-mail.

- Depending on the form, plating may not be possible. Also, the surface condition after plating may be inferior to that of standard molded objects.

Performance of Plating for 3D printed Objects

We have much experience with ABS for FDM, Ultem, Digital ABS, acrylic resins, and many other materials. Please contact us to ask about other materials.

Materials and methods used in prototype plating

| Materials | ABS, Ultem, acrylic, PLA, PA12, PBT, etc. |

|---|---|

| Methods | Fused Deposition Modeling, Laser Beam Lithography, Powder Sintering Process, Ink-jet method, Powder Lamination Method, etc. |

※Some types of resins dissolve in the solvent. Please Contact Us for details.

※We will perform tests for other materials. Please Contact Us for more information.

We can recommend the best method for your requirements

- We can recommend the best method for your requirements

■is there any way we can decorate it?

■is there any way to harden surface?

■can we make it more corrosion resistant?

■is there any way to make it slide more smoothly?

…and so on.

We can recommend the best plating method to meet your needs!