The Plastic Plating Industry

PRODUCTS

-

We established the technology to perform mass production of plastic plating approximately 50 years ago. Indeed, in the history of plastic plating, high-volume production throughout the world began at about that same time. So it could be said that, in regard to plastic plating, we are one of the world’s long-established plating companies.

With the accumulation of 50 years of experience, we can provide small lots of multiple products that other companies can’t manage, and we have a wide range of plating, with strong adhesion to many different materials. -

Computer-managed Line supporting Random Production

-

Integrated Production System

Our “Integrated Production System” makes possible higher precision, shorter delivery time, and lower cost.

Ask us about the integration from mold-making to final assembly.

【Mold】→【Casting】→【Plating】→【Painting/Printing】→【Assembly】

We process from one-off pieces to test production runs.

-

- We are willing to do a variety of jobs: machined and laser-etched objects, urethane castings, one-off samples, pre-production test samples, small-lot production items, and more.We have more than 50 colors of plating, which can be applied to all processes. And our Sample Catalogue makes color confirmation easy.If you have questions about surface processing, (for example, you are not sure about whether a material is suitable for plating, or which plating is best-suited for a certain form) don’t hesitate to Contact Us .

4 Special Feature

Characteristic1

We can plate with a variety of colors!

-

-

Plating refers to applying a thin coating of metal to a surface.

Here at Tsukada Riken, we have a wider range of metals that we use for plating than most other companies.

For plating, the kind of metal used determines the color of the plating.Besides standard metals like Chrome (Cr), Gold (Au), and Nickel (Ni), we use other metals like Tin-Cobalt (Sn-Co), for a total of 14 colors of metallic plating for use in mass production.

Most plating companies only use about 3 kinds of metals.

Characteristic2

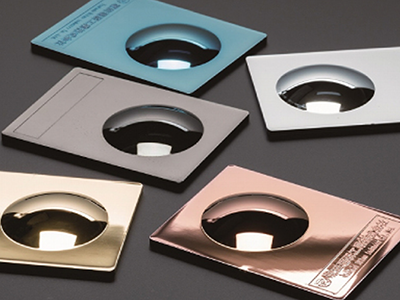

Four Levels of Finish, from Glossy to Satin

-

-

We are able to create four levels of finish in our plating, from the shiny, glossy chrome finish (TP10) that most people associate with plating, to a mildly shiny pearly satin finish (TP43-Cr), to an even stronger satin texture with more of a matte finish (TP40-Cr).

Most plating companies provide one type of glossy plating, or occasionally have a second satin finish available.

Characteristic3

We have the skill to plate even hard-to-plate materials!

-

-

In most cases, when talking about plating plastics, ABS is the medium used. However, depending on the use, ABS may not be suitable.

For example:

・We want a higher heat resistance limit.

・We need something harder!

・We want something that deforms less with temperature change.

・We want something that doesn’t have sharp edges when broken.

And so on.

Plating doesn’t adhere with normal processes for most engineering plastics that meet these criteria.We at Tsukada Riken have the expertise for dealing with these hard-to-plate materials. We can perform plating on some 20 other plastics besides ABS.

Characteristic4

By combining with painting, we can offer a variety of surfaces.

-

-

By painting on top of the plating, we can create a serene, luxurious texture that can’t be attained with only paint or only plating. And with the ability to provide a wide variety of processes without losing the metallic feel, the possibilities for surface treatment are greatly enhanced.

・High-adhesive paint on the plated surface(Many examples of this are used in the automotive industry)

・Unlimited variety of color variations

・A high level of reliability using the latest equipment

・Partial painting using masking – able to create both glossy and grainy textures on the same material.・We can also provide the popular “piano black”.

Remember regarding Plastic Plating Design

IMPORTANT POINT

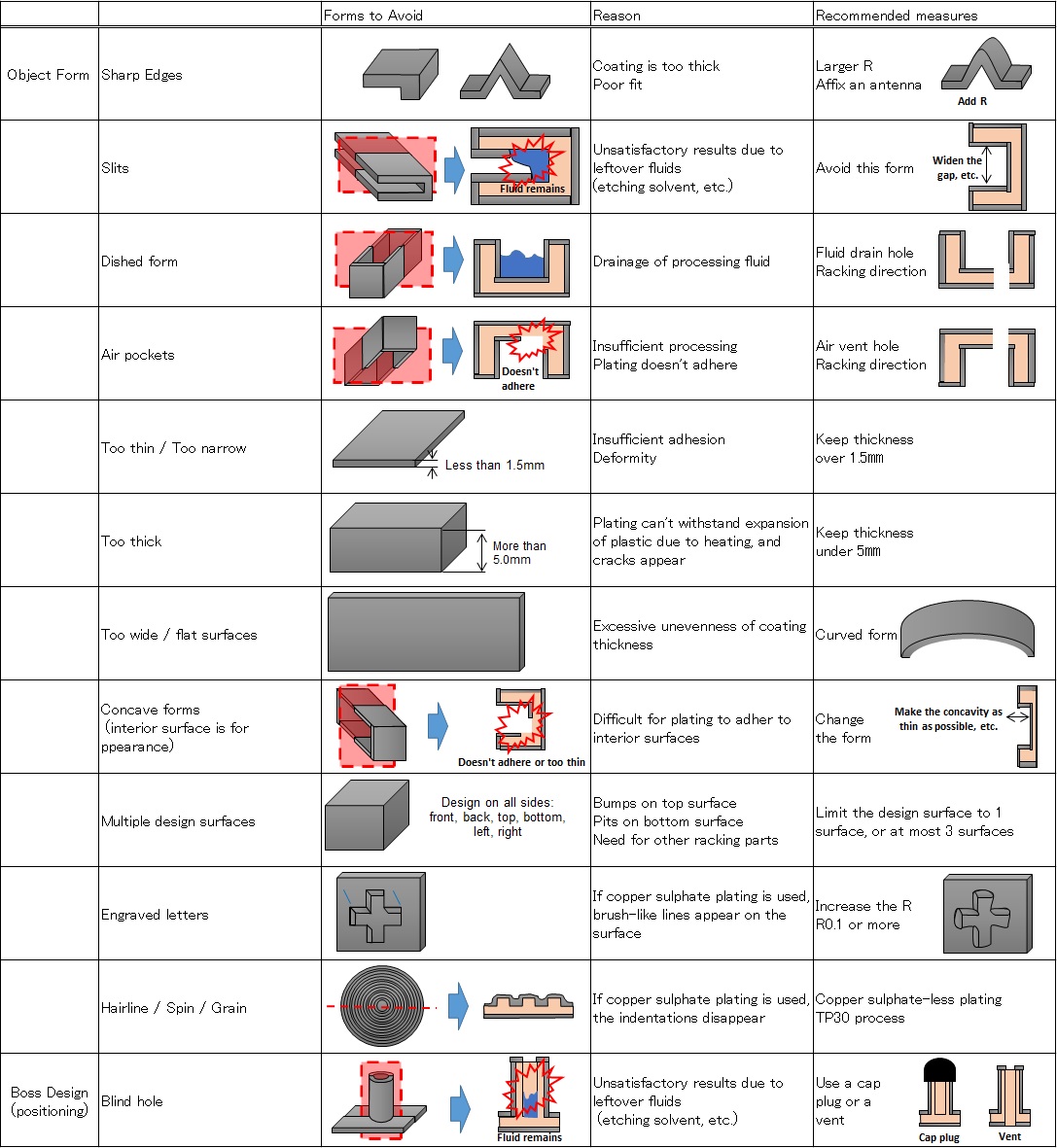

Plated Products Points to Remember regarding Design

When you are designing products geared for plastic plating, there are several things to keep in mind to facilitate better visual results, lower reject rates, and lower costs during production. Be sure to consider them. There are also several methods to improve plating ability depending on the form of the product. Please ask us.